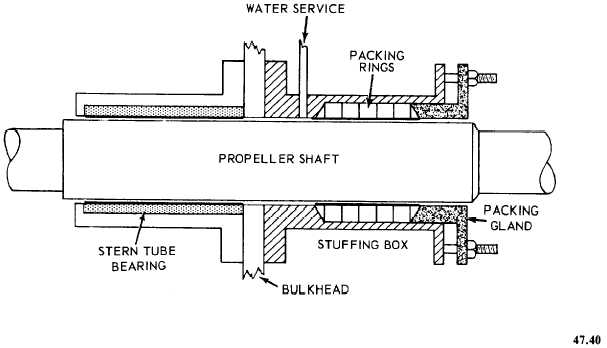

The Stern tube is a narrow hole in the hull structure at the rear end of the ship/boat that connects the propulsion shaft and the engine and the propeller. Purpose of Stern tube is to support the shaft. It forms the after bearing for the propeller shaft and to make water tight joint/gland where the shaft passes through the hull.

Two types of stern tubes are in common use, one with water lubricated bearings with the after end open to the sea & the other type is closed at both ends and has metal bearing surfaces lubricated by oil.

Water lubricated stern tube

|

| Image credit: http://www.marineengineering.org.uk |

- The tube is usually constructed of cast steel with a flange at its forward end & a thread at the aft end.

- Also at the aft end, tube has small flange cast on it. ( we can say this as collar)

- the tube is inserted from the forward end and the flange is bolted to the aft peak bulkhead with a gasket to ensure water-tightness.

- A steel nut placed on the thread at aft end retain the tube in position with its collar hard against the stern frame.

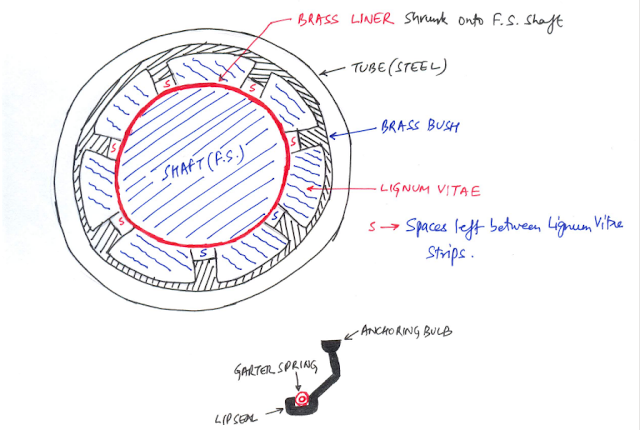

- Inside the tube is a brass bush which has grooves in it, running fore and aft.

- Strips of lignum vitae ( a resinous dense hardwood) are fitted into these grooves to act as bearing for the shaft.

- Small spaces are left between the lignum vitae strips. Through these spaces water can enter to lubricate and cool the shaft.

- A check ring bolted on the after end of the tube, keeps the strips in place.

- A stuffing box/water tight gland is fitted at the fore end of the tube ----- to prevent water from getting into machinery or tunnel space but slight leakage is allowed to ensure cooling of this packing.

- A brass/gunmetal liner is shrunk fitted to the tail end shaft, usually for the full length of the stern tube.

- Bearing length is 4 times the shaft diameter.

- Natural lubrication assisted by SW.

- Predictable wear rate allows scheduling of dry-docking in advance.

- No sophisticated forward/aft seals required.

- No chances of pollution due to leakage of oil into water as in case of oil lubricated type.

Nearly all outboard bearings were water lubricated until about 1960, when transition to oil lubricated bearing begin due to following drawbacks:

Excessive wear-down of bearing materials was caused by the trend to larger ship sizes, which had higher bearing loads. Also Larger ships generally operate at deeper drafts; and with less clearance between the hull and the channel bottom more contaminants, such as silt, mud and sand are drawn into the bearing clearance causing their wear down.

Poor quality of work when rewooding, inferior materials, presence of sand, sediments in the water required early rewooding. Vessels with engine aft, and particularly tankers & ore carriers which spend long periods in ballast sometimes rewooding is required in 18 months. Shaft needs extra liner for SW corrosion protection.

By using oil lubricated stern tube bearings above problems can be eliminated. Oil lubricated stern tube bearings also reduce the power loss in the shafting system. Also oil is better vibration damper & superior lubricant than water

Oil lubricated Stern tube

- White metal lined with oil grooves , cast iron or bronze bush replaces wood lined brass bush.

- Shaft is protected from metal-to-metal contact with bearing by oil lubrication which is supplied from a header tank in the Engine Room.

- a minimum bearing length of 2 times of shaft diameter will ensure that bearing load does not exceed 0.8N/mm2

- propeller shaft has 2 short rotating liners of chrome steel.

- Liner at after end is bolted to the Propeller boss. Inboard liner is fixed by clamping ring.

Aft Seal

It is composed of casing fixed to stern frame and chrome steel liner which is fixed to propeller boss & rotates with propeller shaft. Ingress of sea-water is prevented by fitting a rubber sealing ring between Propeller boss and the chrome liner.

The casing which is stationary part consists of 3 types of metal rings:-Flange ring, Intermediate rings and Cover rings which are tightened to each other with bolts. These metal rings contains the sealing rings which may be 3 or 4. In our case we discuss 3 sealing rings. The leading edge(lips) of the rings are pressed hard against the rotating liner by the water and oil pressures, elasticity of the rubber material and the tightening force of the springs to maintain sealing effect.

The sealing rings are numbered 1,2,3 from the SW side.

Two outer sealing rings (made of VITON or NITRILE BUTADIENE RUBBER also called NBR which is oil & water resistant) are fitted to prevent SW penetrating the lub oil space. Viton sealing rings are particularly excellent in heat resistant property.Sealing ring also has the function of protecting the inside of the stern tube from the foreign matter in the SW.

Inner sealing ring fitted in the opposite fashion, prevents the oil in the stern tube leaking into the sea. Garter spring --- held the sealing rings on rotating chrome liner.

Normally 2 gravity tanks (High & Low) are provided for oiling for deep draft and shallow draft condition so that oil pressure can be set approx 0.2 to 0.3 bar more then SW pressure applied to the centre of tail shaft so as to prevent SW from penetrating into the S/T. Please follow the specific instructions while changing over from high to low gravity tank & vice versa.

Forward Seal

It is of similar construction to the aft seal. Only 2 sealing rings are used running against on chrome liner preventing leakage of oil into Engine Room. Oil is supplied by gravity tank installed approx 0.5 m above the top of the casing.

Disadvantage of Oil lubricates seals:

- White metal debris may choke and restrict oil supply, speeding up failure.

- Contaminated oil supply, causes abrasive wear.

- Lack of oil supply can happen due to low level in header tank/obstructed flow/damaged pipework.

- If using high gravity tank in ballast condition, chance of oil leakage into sea (in case of seal failure), causing oil pollution.

Stern Tube wear down measurement

Stern tube bearing wear down is measured by Poker gauge. Values measured are recorded on the recording board in the wear down gauge. Initial measurement is taken when ship has been completed and the shafting/propeller and the seals have been installed completely. This is the reference measurement. Measurements thereafter shall be taken normally each time the ship goes to the dock, and values measured are compared with those measured previously.Split type stern tube (Ross-turnbull)

The roller lower half is machined in the two horizontal front and rear surfaces machined in the rear frame. The bearing is held in a vertical position by two bushes 50 tons of tap pilger, determines the thickness of the spacer around the height of the bearing. These cats also hold the two halves of the camp. The lateral positioning of the bearing is formed by two types of 30 pilgrim tonnes arranged on both sides of the carrier cat.

A bearing ring is arranged above the bearing to facilitate easy transport of the upper half of the rollers, are provided at the bottom with rolling bearing to enable transport from the lower half. After removal of the lower half of the bearing, the first cylinder is arranged below the elevator free of its mounting gaps. Then the washers are removed and the base is resting on the rollers. The weight of the propeller and the shaft is integrated into the rear by a fork support structure.

Stresses in tail shafts and stern tube

Due to the considerable weight of the propeller, the axis of the tail is subjected to bending. However, there are also other reasons which are likely possible. There is a torsional stress due to the drag torque of the propeller and the motor/engine, and a compressive stress due to the pressure support.All these tensions, and that the tree can be in contact with highly corrosive seawater, makes the probability of an attack corrosion is very likely.

Examining a tail shaft and stern tube

- It is necessary to measure bearing wear before regular inspection.

- To remove the stem after thorough examination.

- In setting bronze coating integrity of the water lubricated shaft must be checked by knocking with a hammer on its entire length to hear its hollow indicating separation.

- Measuring the wear of the shaft.

- Examine the button shaped cracks.

- Replace the rubber rings.

Author Amit

Post a Comment