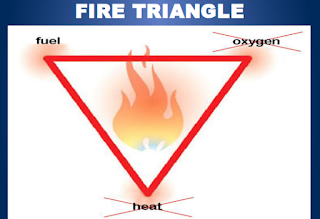

FIRE TRIANGLE: IF ANY ONE SIDE OF “FIRE TRIANGLE” IS REMOVED, FIRE WILL BE EXTINGUISHED.

METHODS OF FIRE FIGHTING: THERE ARE FOUR METHODS OF FIGHTING FIRE

- SMOTHERING – REMOVING THE AIR.

- STARVING - REMOVING THE BURNING MATERIAL FROM THE SURROUNDING.

- COOLING – REMOVING THE HEAT.

- INHIBITING – RETARDATION OF THE COMBUSTION REACTION.

Types of fire

In the European Standard "Classification of fires" (EN 2:1992, incorporatiing amendment A1:2004), the fires are classified as:

Class A fire: Ordinary combustibles such as wood, paper, carton, textile, and PVC;

Class B fire: Flammable liquids and solids which can take a liquid form, such as benzene, gasoline, oil;

Class C fire: Flammable gases, such as butane, propane, and natural gas;

Class D fire: Combustible metals, such as iron, aluminum, sodium, and magnesium;

Class F fire: Cooking media, such as oils and fats, in cooking appliances;

A fire involving energized electrical equipment is not classified by its electrical property.

SMOTHERING

IF THE OXYGEN CONTENT OF THE ATMOSPHERE IN THE

IMMEDIATE NEIGHBORHOOD OF BURNING MATERIAL CAN BE SUFFICIENTLY REDUCED

COMBUSTION WILL CEASE. THIS PRINCIPLE IS INEFFECTIVE IN THE CASE OF

CELLULOID AND SIMILAR SUBSTANCES, WHERE BURNING OF THE MATERIAL CONTAINS

WITHIN ITSELF, IN A CHEMICALLY COMBINED FORM.

PRACTICAL ASPECT: ON A SMALL SCALE IT IS EMPLOYED IN A SNUFFING CANDLE. PERSONS CLOTHING CAN BE SMOTHERED WITH A RUG / BLANKET

ON

A LARGE SCALE, IN CAPPING A BURNING WELL. BATTERING DOWN OF A SHIP’S

HOLD WHEN A FIRE BREAKS OUT BELOW DECKS WILL OFTEN HOLD THE FLAMES IN

CHECK UNTIL PORT IS REACHED.

PRACTICAL APPLICATION OF SMOTHERING METHOD

- USE OF FOAM: THIS FORMS A VISCOUS COATING OVER THE BURNING MATERIAL AND LIMITS THE SUPPLY OF AIR.

- USE OF DRY POWDER: SODIUM BICARBONATE FROM A PRESSURIZED EXTINGUISHER. CARBONATE WHEN FINELY DIVIDED ABSORB HEAT AND THUS HAS COOLING AND FLAME INHIBITING EFFECT.

- USE OF INERT GAS: THE VIGOROUS DISCHARGE OF INERT GAS, SUCH AS CARBON DIOXIDE & NITROGEN IN THE IMMEDIATE VICINITY OF THE FIRE REDUCES THE OXYGEN CONTENT OF ATMOSPHERE BY PROVIDING A TEMPORARY BLANKET EFFECT.

STARVATION

THE EXTINCTION OF FIRE BY STARVATION IS APPLIED IN

THREE WAYS. BY REMOVING COMBUSTIBLE MATERIAL FROM THE NEIGHBORHOOD OF

THE FIRE.

Ex: DRAINING OF FUEL FROM BURNING OIL TANKS, DISCHARGING OF CARGO AT A SHIP FIRE.

BY REMOVING THE FIRE FROM THE NEIGHBOURHOOD OF COMBUSTIBLE MATERIAL.

Ex: PULLING APART A BURNING HAYSTACK.

BY SUB-DEVIDING THE BURNING MATERIAL.

Ex: SMALLER FIRES PRODUCED MAY BE EXTINGUISHED MORE EASILY, SUCH AS EMULSIFICATION OF THE SURFACE OF BURNING OIL.

COOLING

THE PROCESS OF REMOVING THE HAET FROM FIRE IS CALLED COOLING. THIS

IS NORMALLY DONE BY WATER, AS WATER HAS MORE COOLING EFFECT AND VERY

HIGH LATENT HEAT. APPLICATION OF JET OR SPRAY OF WATER TO A FIRE, EMULSIFICATION OF THE SURFACE OF OIL BY MEANS OF THE EMULSIFYING TYPE OF SPRINKLER HEAD.

INHIBITING

IN

THIS HEAT PRODUCING CHEMICAL REACTION OF SUBSTANCES IS CHECKED OR

STOPPED. THIS APPLIES TO ONLY FLAMING MODE AND NOT TO THE GLOWING MODE.

IN THIS FLAME INHIBITING EXTINGUISHING MEDIUM INTERFERES WITH THE ACTIVE

SPECIES IN FLAME CHAIN REACTION WHICH WOULD OTHERWISE FUNCTION AS

“CHAIN CARRIERS”. THIS METHOD EXTINGUISHES THE FLAME VERY RAPIDLY.

Ex: DCP OR HALON GAS – THESE ACT BY CHEMICAL INTERFERENCE WITH THE CHAIN REACTION OF FLAME PROPAGATION.

PROPERTIES OF FLAMMABLE MATERIAL

FLAMMABILITY: THIS

IS THE ABILITY OF SUBSTANCE TO BURN. IN THIS VAPOR GIVEN OFF BY

FLAMMABLE MATERIAL CAN BURN WHEN MIXED WITH AIR IN THE RIGHT PROPORTION

IN THE PRESENCE OF AN IGNITION SOURCE.

IGNITION POINT: IT IS THE LOWEST TEMP., TO WHICH A FLAMMABLE SUBSTANCE MUST BE HEATED TO IGNITE.

FLASH POINT:

IT IS THE LOWEST TEMP., AT WHICH THE VAPOUR OF THE SUBSTANCE ARE

AVAILABLE IN SUFFICIENT QUANTITY TO PRODUCE A MOMENTARY FLASH WHEN A

FLAME IS APPLIED.

FIRE POINT: IT IS THE TEMP.,

AT WHICH THE HEAT FROM THE COMBUSTION OF BURNING VAPOR IS CAPABLE OF

PRODUCING SUFFICIENT VAPOUR TO ENABLE COMBUSTION TO CONTINUE.

SPONTANEOUS / AUTO / SELF IGNITION TEMP:

IT IS THE LOWEST TEMP., AT WHICH THE SUBSTANCE WILL IGNITE

SPONTANEOUSLY i.e., THE SUBSTANCE WILL BURN WITHOUT THE INTRODUCTION OF A

FLAME OR OTHER IGNITION SOURCE.

UPPER FLAMMABLE LIMIT: IT IS THE CONCENTRATION OF FLAMMABLE VAPOUR IN AIR ABOVE WHICH THE MIXTURE BECOMES TOO RICH TO IGNITE AND PROPEGATE COMBUSTION.

LOWER FLAMMABLE LIMIT:

IT IS THE CONCENTRATION OF FLAMMABLE VAPOUR IN AIR BELOW WHICH THERE IS

INSUFFICIENT FLAMMABLE VAPOUR TO SUPPORT AND PROPAGATE COMBUSTION.

STATIC ELECTRICITY:

IT IS THE ELECTRICITY PRODUCED IN DISSIMILAR MATERIALS THROUGH PHYSICAL

CONTACT AND SEPARATION i.e., A SAMPLING APPARATUS LOWERED IN TO A TANK

CONTAINING CHARGED PETROLEUM LIQUID.

FLAMMABLE RANGE: IT IS THE RANGE OF CONCENTRATION OF A FLAMABLE VAPOUR IN AIR WITH WHICH THE VAPOUR AND AIR MIUXTURE IS FLAMABLE.

FLAMMABILITY: IT

IS THE ABILITY OF SUBSTANCE TO BURN VAPOUR GIVEN OFF BY A FLAMMABLE

MATERIAL, WHEN MIXED WITH AIR IN RIGHT PROPORTION IN THE PRESENCE OF THE

IGNITION SOURCE. NORMAL AIR CONTAIN - 21% OF O2 AND 78% OF N2 AND

SMALL TRACES OF CO2 , WATER VAPOUR etc. IN CARGO TANKS AS THE PERCENTAGE

OF HYDROCARBON INCREASES, OXYGEN CONTENT DECREASES.

LOWER FLAMABLE LIMIT (LFL): FOR

A MIXTURE OF AIR AND THE FUEL TO BE COMBUSTIBLE, MINIMUM QUANTITY OF

THE FUEL VAPOUR SHOULD BE PRESENT IN THE MIXTURE. THIS IS EXPRESSED AS

PERCENTAGE OF FUEL VAPOUR IN THE MIXTURE OF AIR AND VAPOUR. THIS IS

CALLED LOWER FLAMABLE LIMIT. THE MIXTURE WILL NOT BURN UNLESS FUEL

VAPOUR CONTENT IN THE COMBUSTIBLE MIXTURE IS ABOVE LFL.

EVERY TYPE OF FUEL HAS DIFFERENT LFL.

POINT “F” – MINIMUM OF O2 REQUIRED FOR COMBUSTION ( 11% BY VOLUME).

LFL – LOWER FLAMABLE LIMIT

– 1% OF C2H2 AT POINT “A”

UPPER FLAMABLE LIMIT (UFL):

WHEN

THE PERCENTAGE OF FUEL VAPOUR IS INCREASED IN THE MIXTURE, THE

PERCENTAGE OF AIR AND HENCE THE PERCENTAGE OF OXYGEN REDUCES.

SINCE

THE OXYGENN CONTENT BELOW 11% IN THE MIXTURE DOES NOT SUPORT

COMBUSTION, A STAGE MAY BE REACHED WHEN THE PERCENTAGHE OF VAPOUR IN THE

MIXTURE IS SO HIGH THAT RESULTING PERCENTAGE OF OXYGEN IS TOO LOW TO

SUPORT THE COMBUSTION AND MIXTURE WOULD NOT BURN EVEN WHEN IGNITED. THIS

IS CALLED UPPER FLAMABLE LIMIT.

MIXTURE WILL NOT BURN IF THE FUEL VAPOUR CONTENT MORE THAN THE UFL.

UFL – UPPER FLAMABLE LIMIT

- 11% OF C2H2 AT POINT “B”

EVERY FUEL HAS A LFL and UFL AND THE PERCENTAGE OF FUEL VAPOUR RANGE BETWEEN BETWWEN THESE TWO LIMITS IS CALLED “FLAMABLE RANGE”

POINT

“A” – AT THE END OF BURNING IF THE PRODUCT OF COMBUSTION ARE ANALYSED,

IT IS FOUND THAT ALL OF C2H2 VAPOURS ARE CONSUMED, WHILE SOME “O2” IS

UNUSED AND STILL AVAILABLE.

POINT “B” – AT THE END OF BURNING, ON

ANALYSIS, IT IS FOUND THAT ALL OF “O2” IS CONSUMED AND SOME UNBURNT C2H2

IS STILL AVAILABLE.

SOURCE OF IGNITION (HEAT ENERGY)

- CHEMICAL HEAT ENERGY

- ELECTRICAL HEAT ENERGY

- MECHANICAL HEAT ENERGY

- NUCLEAR HEAT ENERGY

- HEAT OF COMBUSTION

- HEAT OF PARTIAL OXIDATION

- SPONTANEOUS HEATING

- HEAT OF DECOMPOSITION (ONION, POTATO etc., IN CARGO HOLD)

- HEAT OF SOLUTION (MIXTURE OF TWO CHEMICALS)

- ELECTRICAL:

- RESISTANCE HEATING

- DI-ELECTRIC HEATING

- INDUCTION HEATING

- MECHANICAL:

- FRICTIONAL HEATING

- FRICTIONAL SPARKS

- HEAT OF COMPRESSION

CLASSIFICATION OF FIRE

FIRES

ARE CLASSIFIED ACCORDING TO THE TYPES OF MATERIAL WHICH ARE ACTING AS

FUEL. FIRES BURNING WOOD, GLASSFIBRE, UPHOLSTERY AND FURNISHINGS. FIRES

BURNING LIQUID SUCH AS LUBRICATING OIL AND FUELS. FIRES BURNING GAS FUELS SUCH AS LIQUIFIED PETROLEUM GAS. FIRES BURNING COMBUSTIBLE METALS SUCH AS MAGNESIUM AND ALUMINIUM. FIRES BURNING ANY OF THE ABOVE MATERIALS TOGETHER WITH HIGH VOLTAGE ELECTRICITY.

THESE

CLASSIFICATIONS ARE ALSO USED FOR EXTINGUISHERS AND IT IS ESSENTIAL TO

USE THE CORRECT CLASSIFICATION OF EXTINGUISHER FOR A FIRE, TO AVOID

SPREADING THE FIRE OR CREATING ADDITIONAL HAZARDS. MANY FIRE EXTINGUISHER WILL HAVE MULTIPLE CLASSIFICATIONS SUCH AS A, B and D

FIRE EXTINGUISHING AGENTS

CARBON DIOXIDE:

AT NORMAL TEMP., CO2 IS 1.5 TIMES HEAVIER THAN AIR. IT IS EASILY

LIQUEFIED AND BOTTLED. IT IS STORED UNDER PRESSURE OF 50bar IN STEEL

CYLINDERS. WHEN CO2 IS APPLIED TO FIRE, THE LIQUID CO2 BOILS OFF RAPIDLY

AS A GAS, EXTRACTING HEAT FROM THE SURROUNDING ATMOSPHERE. IT

EXTINGUISHES FIRE BY SMOTHERING i.e., BY DISPLACING OXYGEN. ABOUT 20-30 %

OF THE ATMOSPHERE SHOULD CONTAIN CO2 TO EXTINGUISH THE FIRE. CO2 IS

QUICK AND CLEAN, NON-TOXIC, DOES NOT HARM MOST FAFRIC AND DOES NOT

CONDUCT ELECTRICITY. SO IT CAN BE USED ON ELECTRICAL IT DOES NOT DAMAGE

EXPENSIVE CARGO OR MACHINERY. IT LEAVES NO UNDESIRABLE RESIDUE TO BE

CLEARED OFF AFTER USE. SO IT CAN BE USED TO EXTINGUISH FIRE IN CARGO AND

MACHINERY SPACES BY PROVIDING FIXED CO2 INSTALLATIONS.

ADVANTAGES OF CARBON DIOXIDE:

- NON-CORROSIVE.

- DOES NOT CONDUCT ELECTRICITY.

- LEAVES NO RESIDUE.

- EASILY AVAILABLE.

- NOT SUBJECTED TO DETERIORATION IN QUALITY WITH AGE.

- TOXIC AND HAZARDOUS TO HUMAN BEING.

- LITTLE COOLING EFFECT & DANGER OF RE-IGNITION IF AIR IS READMITTED IN ROOM.

- SOLID CO2 PARTICLES GENERATE SPARK DUE TO STATIC ELECTRICITY, SO UNSUITABLE IN OIL TANKERS

IT IS SAFE TO USE ON MOST OF THE FIRES, IT CAN BE EASILY DIRECTED OVER A CONSIDERABLE DISTANCES.

DISADVANTAGES:

- IT CONDUCTS ELECTRICITY.

- IT CAN CAUSE DAMAGE TO CARGO & MACHINERY.

- LOSS IN STABILITY OF SHIP WHEN USED IN LARGE QUANTITY.

IT IS MOST SUITABLE FOR EXTINGUISHING FIRES INVOLVING FLAMMABLE LIQUIDS. IT EXTINGUISHES BY FORMING A LAYER OF SMALL BUBBLES ON THE SURFACE OF THE LIQUID PREVENTING FUEL FROM VAPOURISING AND RESTRICTING THE OXYGEN SUPPLY TO IT.

IT IS INSOLUBLE IN MOST OF THE LIQUIDS AND LIGHT IN WEIGHT, SO IT FORMS A BLANKET TO COVER THE SURFACE OF BURNING LIQUID AND THUS EXTINGUISHES THE FIRE.

FOAM CAN BE GERATED BY MECHANICAL OR CHEMICAL MEANS.

MECHANICAL

FOAM IS GENERATED BY AGITATION OF A DILUTED FOAM COMPOUND SOLUTION IN

PRESENCE OF AIR. THESE COMPOUND INCLUDE SOAPS, GLUE AND WETTING AGENT

MIXTURES. CHEMICAL FOAM IS GENERATED BY MIXING AN ALKALI (SODIUM

BI-CARBONATE) WITH A SOLUTION OF ALUMINIUM SULPHATE, IN PRESENCE OF A

STABILIZER (i.e., SOAP) THIS PRODUCES SKIMMED BUBBLES CONTAINING CO2

“HIGH EXPANSION FOAM” HAS A VERY HIGH EXPANSION RATION OF AROUND 1000 TO

1 INSTEAD OF 8 TO 1 FOR STANDARD FOAM. THIS TYPE FOAM IS USED FOR

DEALING WITH CARBONACEOUS FIRES IN COMPARTMENTS WHICH ARE INACCESSIBLE

AND WHICH LEND THEMSELVES TO COMPLETE FLOODING OF THE COMPARTMENT.

DRY CHEMICAL POWDER:

WATER

CANNOT BE USED ON MOST FIRES AS IT CAN BE EXPLOSIVELY DISASTROUS. IN

VIEW OF THIS OTHER MEDIUMS ARE USED. CHIEF AMONG THEM IS DRY CHEMICAL

POWDER. IN THIS SODIUM BICARBONATE IS USED AS BASIS ALONG WITH ADDITION

OF METALLIC STEARATE AS WATER PROOFING AGENT. DRY CHEMICAL POWDER IS

EXPELLED FROM CONTAINER BY GAS PRESSURE.

IT IS ESPECIALLY

EFFECTIVE ON BURNING LIQUIDS SUCH AS LIQUIFIED GAS, OIL ESCAPING FROM

LEAKING LINES AND JOINTS. ON ACCONT OF IT’S UNIQUE ABILITY TO QUICKLY

STOP COMBUSTION OF GASES, CHEMICAL PRODUCTS etc., IT HAS BECOME MOST

POPULAR MEDIUM IN GAS CACCIERS AND TANKERS. DRY CHEMICAL POWDER IS

ELECTRICAL NON-CONDUCTOR , THUS IT CAN BE UTILISED ON FIRES INVOLVING

LIVE ELECTRICAL EQUIPMENTS. IT INHIBITS THE COMBUSTION REACTION.

Solas convention

The

International Convention for the Safety of Life at Sea (SOLAS) is an

international maritime safety treaty. It ensures that ships flagged by

signatory States comply with minimum safety standards in construction,

equipment and operation.

1974 version

The

intention had been to keep the Convention up to date by periodic

amendments, but the procedure to incorporate the amendments proved to be

very slow,As a result, a complete new convention was adopted in 1974

which includes all the agreements and acceptable procedures. Even though

the Convention was updated and amended numerous times, the Convention

in force today is sometimes referred to as SOLAS, 1974.

The

latest Convention in 1974 included the "tacit acceptance" procedure

whereby amendments enter into force by default unless nations file

objections that meet a certain number or tonnage.

Types of Bulkheads.

'A' Class Divisions

Class

differences "A" are the bulkheads and decks of steel or any other

equivalent material which is capable of preventing the passage of smoke

and flames to the end of the test standard of the hour of fire. They are

well reinforced. They are insulated with unauthorized combustible

materials so that the average temperature of the un-exposed side does

not rise above the initial temperature or temperature at any point above

140 ° C, including any junction, rise above 180 ° C above the original

temperature, Within the time, specified below:

"A-60" 60 minutes

"A-30" 30 minutes

"A-15" 15 minutes

"A-0" 0 minutes.

A

prototype or platform partition should be tested according to the

FireCode test procedure to ensure that it meets the above requirements

for integrity and temperature rise.

Class A fire protection doors

The

construction of the doors in the class A walls and the fastening means

in the closed position provides a fire resistance, such as the passage

of smoke and flames, as far as possible, similar to the bulkheads in

which they are located.

Class A fire-resistant doors, made of steel or an equivalent material.

In These doors should be capable of being opened and closed from each side of the bulkheadby one person only.

Fire

doors in main vertical zone bulkheads, galley boundaries etc., other

than power operated water tight doors should be (1) self closing and and

be capable of safe operation with an angle of inclination of upto 3.5

degrees opposing closure, and in no more than 40 sec. and no less than

10 sec. with the ship in upright position. (3) the doors except for

those for emergemcy escape trunks Shall be capable of of remote release

from the central control stations and should also be capable of release

individually from a position at both sides of the door. Release

switches shall have an on-off function to prevent automatic resetting of

the system. (4) hold back hooks not subject central control station

release are prohibited, (5) a door closed remotely shall be capable of

being reopened locally from both sides of the door and after such

opening, the door shall automatically close again.(6) there should be

fire door position indicator on the indicator .

Indicator

panel in the central control room and the release mechanism shall be so

designed that the door will automatically close in the event of power

supply failure. (7) local power supply accumulators for power operated

doors shall be provided in the immediate vicinity of the doors to enable

the doors to be operated at least 10 times (open and close) after

disruption of the control system or the central power supply using local

controls. (8) the components of the local control system shall be

accessible for maintenance and adjusting.

(9) In the

event of a fire, the control system shall operate the door at the temp.

of at least 200 deg. For at least 60 min. served by the power supply and

the power supply for all other doors not subject to fire shall not be

impaired, and (10) at temperatures exceeding 200 deg. C the control

system shall automatically be isolated from the power supply and shall

be capable of keeping the door closed upto at least 945 deg.C.

'B' Class Divisions

Class differences "B" are the bulkheads, decks, blankets and coatings

Approved

non-combustible materials to prevent sufficient flame to pass through

the end of the first half hour of the standard fire test. They have an

insulation value so that the average temperature of the un-exposed side

does not exceed 140 ° C above the initial temperature or the temperature

at any point, including any junction, rises more than 225oC to the

initial temperature, the following phases:

Class "B-15" 15 minutes

Class "B-0" 0 minutes.

A

prototype or platform partition should be tested according to the

FireCode test procedure to ensure that it meets the above requirements

for integrity and temperature rise.

Class B fire protection doors

The

construction of all doors in the partition type "B" and the means in

the closed position represents the equivalent of fire as far as possible

bulkheads in which the doors of the exception that can lie vent

openings in the lower part of the doors, with a total area of the

lower opening Or equal to 0.05 m2. (1) These doors must be closed.

Retaining hooks are not permitted. The doors of class B fire must be

built with non-flammable materials approved. Class B fire protection

doors built with approved non-combustible materials in accordance with

the test method Code for fire.

Class differences, C '

Class

differences "C" are the non-flammable materials, the bulkheads, decks,

ceilings and linings, which limit requirements for the passage of smoke

and flames or temperature rise. Door Class "C" is the type of doors

installed in the class partitions "C". The approved noncombustible

materials must be constructed.

Fire dampers

Valves

are penetrating into the ventilation ducts installed bulkheads and

bridging the class "A" to maintain the division of fire resistance

capability and prevent the spread of smoke and flames in adjacent

compartments through the ventilation system.

fire integrity

Resistance

to fire is to keep the grounding element's resistance with a bulkhead

or deck intact for a period of time, 60 minutes for class "A" and 30

minutes for class "B".

Fire Detection Systems

The

PURPOSE of this regulation is to detect a fire in the space of origin

and to provide for alarm for safe escape and fire fighting activity.

For this purpose :

(1) Fixed Fire Detection and fire alarm

system installations shall be suitable for the nature of the space,fire

growth potential and potential generation of smoke and gases, (2)

manually operated call points shall be placed effectively to ensure a

readily accessible means of notification and (3) fire petrols shall

provide an effective means of detecting and locating fires and alerting

the navigation bridge and fire teams. Fire Detection Systems. – General

Requirements.

A fixed fire detection and alarms system shall be provided as per this regulation.

A

fixed fire detection and alarm system and a sample extraction smoke

detection system required as per regulations mentioned in Chapter II-2,

Part C, of SOLAS shall be of an approved type and comply with Fire

Safety Systems Code.

The function of such systems shall be tested under varying conditions of ventilation after installation.

Such

installed systems shall be periodically tested for proper functioning

under simulated fire conditions to the approval of Administration.

Detection in Machinery Spaces:

A

fixed fire detection and fire alarm system shall be installed in (i)

periodically unattended machinery spaces and (ii)m/c spaces containing

all automatic and remote control systems and equipment approved in lieu

of continuous manning of the space and also in continuously manned

spaces having a central control room.

This system shall be so

designed and installed that all the fire detectors of suitable type

will be capable of detecting the smoke or fire rapidly in any part of

the spaces under working varying condition of temperature and

ventilation.

Detection in Accommodation and Service Spaces and Control Stations:

(1)

Smoke detectors shall be fitted in all stairways, corridors, and escape

routes and if found necessary, special purpose smoke detectors shall be

fitted within ventilation ducting.

Fire Extinction Systems. – General Requirements

This system is brodadly divided in three parts:

Regulation

8 of Part C of Chapter II-2 of SOLAS. Control of Smoke spread : For

this purpose, means of controlling smoke in atriums, control m/c spaces

and concealed spaces shall be provided.

For example, in most

cargo ships of any type of all the supply air fans (usually 4) for

machinery spaces, at least one fan is reversible and can be used as an

exhaust fan in the event of fire and generation of smoke in the m/c

spaces.

In accommodation, gallies, Navigation Bridge, Steering

Flat a provision for exhaust fans is made to expel smoke from the

concerned spaces.

(2) Regulation 9 of Part C of Chapter II-2 of SOLAS.

Containment of Fire: For this purpose (i) the ship shall be subdivided by thermal and structural boundaries,

(ii) thermal insulation of boundaries shall have due regard to the fire risk of the space and adjacent spaces,

(iii)

The fire integrity of the divisions shall be maintained at openings and

penetrations by using approved materials and methods by adhering to the

relevant regulations of the SOLAS.

(3) Regulation 10 of Part C of Chapter II-2 of SOLAS.

Fire

fighting: For this purpose, following functional requirements will be

met : (A) fixed fire extinguishing systems shall be installed, having

due regard to the fire growth potential of the protected spaces, and (B)

adequate number of approved type of fire extinguishing appliances shall

be readily available.

(C) Water supply systems with approved

type and sufficient number of fire pumps, fire mains, hydrants, hoses

and nozzles complying with the regulations of the SOLAS requirements

shall be provided.

(i) Fire mains and hydrants materials readily rendered ineffective by heat shall not be used.

(ii)

Their arrangement shall be such as to avoid the possibility of

freezing, with adequate provisions for the drainage of the mains.

The

number and position of hydrants should be such that at least two jets

of water from two different hydrants may reach any part of the ship.

There will be an isolating valve and a relief valve on the fire main line as approved by the regulations.

Pressure at the hydrants: For cargo ships above 6000 grt it should be 0.27N/mm2.

(vi)

Fire pumps : For cargo ships of 1000 grt and above, there will be at

least two independently driven fire pumps, which will have the

provision for being started and stopped by local and remote switches

(normally situated on the Bridge).

Emergency fire pump : The

space containing the emergency fire pump shall not be contiguous to the

boundaries of the m/c spaces or those spaces containing main fire

pumps. There will be no direct access between the m/c space and the

emergency fire pump spaces.

The emergency fire pump shall have two

sources of electrical power supply, one from the power mains and the

other from the emergency generator bus bars.

Ventilation

arrangements to the emergency fire pump spaces shall be such as to

preclude the possibility of smoke from m/c space fire entering or being

drawn into the space.

(viii) Fire hoses shall be of non perishable

material approved by the Administration and should have a length of at

least 10 mtrs, but not more than 15 mtrs in m/c spaces and not more

than 25 mtrs for open decks on ships with breadth in excess of 30 mtrs.

(ix)

Standard nozzle sizes shall be 12mm, 16mm and 19 mm. For accom. Spaces

a nozzle size greater than 12 mm and for cargo spaces a nozzle size

greater than 19 mm need not be used. The size should be adequate to

obtain the max. discharge possible from two jets at the approved

pressure. Nozzles shall be of approved dual purpose type( i.e.

spray/jet) incorporating a shut off.

(x) Portable fire extinguishers: Their type and design shall comply with the requirements of the Fire Safety systems Code.

Ships

of 1000 grt annd above will have at least 5 portable fire extinguishers

in accom. Spaces, service spaces and control stations. CO2 fire

extinguishers shall not be placed in accom. Spaces. In control stations

and other spaces containing electrical or Or electronic equipment,

only those fire extinguishers whose extinguishing media are not

electrically conductive or harmful shall be used.

Spare charges

shall provided for 100% of the first ten extinguishers and 50% for the

remaining fire extinguishers capable of being recharged on board.

Instructions for recharging shall be carried on board.

(xi) Fixed

fire extinguishing systems: These systems for m/c spaces may be any of

the following types: Fixed gas fire extinguishing system, a fixed high

expasion foam fire extinguishing system or a fixed pressure water

spraying fire extinguishing systems, all complying with the provisions

of the Fire Safety Systems Code.

Here fire extinguishing systems using Halon 1211, 1301, and 2402 and perfluorocarbons shall be prohiibited.

(xii)

There shall be at least one portable foam applicator unit complying

with the provisions of the Fire Safety Systems Code. In addition, in

each space, approved foam type fire extinguishers each of at least 45

ltr capacity shall be provided. Additionally, there shall be provided a

sufficient number of portable foam extinguishers so located that no

point in the space more than 10 m walking distance from an extinguisher

and that there are at least two such extinguishers in each space.

(xiii)

Paint Lockers shall be protected by (i) Co2 system designed to give a

minimum volume of free gas equal to 40% of the gross volume of the paint

locker, (ii) a dry powder system giving at least 0.5 kg powder/m3 of

the space, (iii) a water spraying or sprinkler system connected to

ship’s fire mains designed for 5 ltr/m2 /min. All above systems shall

be operable from outside the protected space.

(ivx) Fire

Extinguishing systems for cargo spaces: Fixed Co2 or inert gas system

complying with the provisions of the Fire Safety System Code. For cargo

tank protection on Tankers a fixed deck foam fire extinguishing systems

complying with provisions of the Fire Safety System Code shall be used.

(xv)

Approved Fire Fighter’s Outfits (atleast two in nos.) shall be carried

by all ships. Additionally, on tankers two extra sets will be carried.

# The article was written by two author and then merged before publishing. Various books are used as reference before writing this article but no part is being reproduced but stated in a different easy way.

# Cover image credit: Pintrest (If you have any problem regarding the post contact us!)

Author Arpit Singh & Amit

# The article was written by two author and then merged before publishing. Various books are used as reference before writing this article but no part is being reproduced but stated in a different easy way.

# Cover image credit: Pintrest (If you have any problem regarding the post contact us!)

Author Arpit Singh & Amit

Post a Comment