A device to display the current position of the rudder installed in

the control house of the bridge. In the angle indicator system Rudder is

independent of the steering system and is only for the display. There

is an IMO requirement which states regardless of the steering control

system there must be installed steering indicator system installed on

board. The specification of the rudder angle is required for each

cockpit and steering position in the rudder emergency room.

The

various regulatory authorities vary the requirements of the Rudder

Level Indicator (RAI). DNV needs a second angle indicator independent

bar on deck. Regulation of the Panama canal requires large instruments

(min 192x192mm) Bridge, visible wing operator and IMO pull to train /

MED (ISO 20673) requires that the accuracy of the system is over a

degree.

Rudder angle indicator consists of a control

unit, a transmitter and receiver. This includes indicators with

different dimensions, different scales and rudder angle display.

A

rudder angle indicator consists of a transmitter and a receiver

direction of the rudder rudder. The emitter is connected to the steering

head by means of a lever, etc. in the wheel housing. Communicates

rudder direction and rotation angle for self-synchronization of the

machine in the sender and causes the self-synchronization of the

machine, in the receiver that I have in the wheelhouse or another that

is for with their directions of synchronicity. Self-synchronous

transmitters and display units used in the control angle display systems

are manufactured by various companies refer to names such as Selsyns,

Synchro, and Automatic Syns Telmotors.

|

| Non Follow-up Steering System |

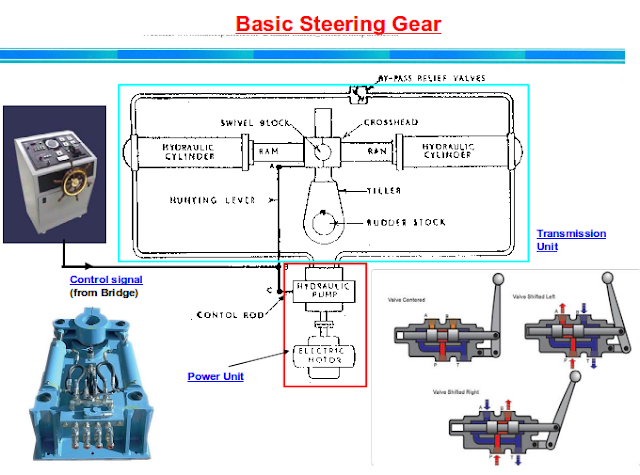

Control equipment – conveys a

signal of the desired rudder angle from the bridge to the steering flat

where it is received to activate the power unit and transmission system

until the desired rudder angle is reached. This equipment can be of 2

types (1)hydraulic telemotor systems (tele- means far away in Greek

& motor means motion or movement) & (2) electrical electronic

control equipment.

Hydraulic telemotor systems: The

telemotor employs master and slave principle. The transmitter is

situated on bridge and the receiver at the steering gear unit.

Mechanical movement is transduced hydraulically or electrically for

distance telemetering and is then transduced back again.

|

| Auto & Follow up Steering System |

Hydraulic

Transmitter: As the bridge steering wheel is moved to starboard the

rotating pinion causes the RH ram to move down, pushing oil out to the

receiver unit along the RH pipe. The LH ram moves up, so allowing a

space for oil to come from the receiver unit. The fluid being virtually

incompressible, any down movement of the RH produces an identical

movement at the receiver unit. This in turn displaces the same quantity

of fluid which is taken up in the extra space created by the LH ram

moving up. The fluid in the replenishing tank acts as reservoir. The

casing is usually gunmetal with bronze rams, and copper pipes are led in

by drilled leads in the casting. A device (called bypass valve) is

required in the system to allow for variation in oil volume due to

temperature changes and also to allow for equilibrium between both sides

of the system. This bypass valve also has function of topping up the

system in the case of leakages and acts as relief valve in case of

pressure rise.

Bypass valve: Operation can only be

carried out when the wheel is in the mid position. This is achieved by

having the operating rod butting against a circular disc, in mid

position of the wheel the slot in the driven revolving disc allows the

operating rod to be depressed through it. With some types the operating

rod is depressed by hand, whilst with some types the rod is

automatically depressed by a cam each time the wheel passes mid

position. In case of hand operated types the rod is operated at regular

intervals and must be operated when either pressure gauge registers

above 4.5 bar with wheel in mid position. When the rod is depressed both

sides of system are connected thus giving pressure balance. The

connection to the replenishing tank is also joined to both sides of the

system, so that any expansion or contraction of the oil can be

compensated.

Hydraulic Receiver: Consider

the starboard (clockwise) movement of the bridge wheel. The depressed RH

ram pressurizes the right hand side of the system. The pressure force

acts on the central web of the moving cylinder until the movement caused

corresponds to the movement of the ram in the steering telemotor. Oil

is pushed back on the left hand side of the moving cylinder central web

to the steering unit. After a small initial movement the LH sleeve butts

against the nut and further movement by the moving cylinder to the left

compresses the springs. When the steering wheel is returned to mid-ship

the springs, which are under initial compression, return the moving

cylinder to mid position. For port wheel rotation the LH ram of the

steering unit moves down and the receiver moving cylinder goes in the

opposite direction i.e. in this case left to right.

The moving

cylinder is connected by a linkage to the control unit of the steering

engine. Thus any movement of the bridge telemotor unit by wheel rotation

is almost directly operating the control device which causes rotation

of the steering engine and rudder movement.

electrical

electronic control equipment: This system is based on the electrical

and electronic circuits, the monitoring and control of the valves, which

control the movement of the rudder. The system also includes a logic

circuit that prevents the side rudder from reaching its physical limits.

In the steering system can only work, under preset electronic limits.

When the bar has reached a limit, the power of the solenoid valve closes

automatically.

|

| Electronic Steering Control |

The system consists of the following

parts: The control unit transmits to the angle of the desired direction

from the bridge in the direction of the plane,Hand Steering without

follow-up, Hand Steering with follow-up and Auto Steering using Gyro

Compass.

The power supply provides the energy to move

the rudder at the desired angle and the transfer unit to move the

motions of the rudder.

The central steering of the

movement of the rudder affect the ship's engines control. And rudder

actuators single unit servo steering is the torque means is applied to

the i-th rudder shaft. Lance or Quadrant

Control system

of the device by means of which the commands from the computer to the

power units of the steering mechanism and other necessary parts are

transmitted to operate the steering. Including transmitters, receivers,

hydraulic control pumps and motors associated hoses and cables.

The

rudder actuator, the element that directly moves to a hydraulic

pressure on the mechanical effect moves the rudder. Wheel drive means

that the parts that transfer the force from the actuator to the aileron

of the flow including the rudder. Power unit means:

- in the case of electrical steering gear ; an electric motor and its associated electrical equipment

- in case of electro-hydraulic steering gear ; an electric motor and its associated equipment and connected pump

- in case of other hydraulic steering gear ; a driving engine and connected pump

Steering Gear Regulations

1.Every ship is to

be provided with two power unit (main and auxiliary) steering gear, each

independent of the other. This is because if one fail another can take

over the power. If however two identical power unit is available, the

presence of stand-by(Auxiliary) is not required.

2.The

capacity of the unit must be such that, it may swing the rudder from

35º on one side to 35º to the other side of the ship with the maximum

speed and at deepest draft.The time required to do so must not exceed 28

Seconds.

3.Steering gear must be power operated if

rudder stock diameter is greater than 120mm. Mostly we use hydraulic

power for operating the rudder post.

Power of the

auxiliary steering shall be such that rudder can be swung from 15º on

one side to 15º to the other in 60 seconds at deepest draft and of 7

knots.

5.Steering gear should be prevented from any

abnormalities, such as overloading, short circuit, overload, and visual

and audible indicator should be available on bridge, ECR and steering

gear room, alarms and trips is also present to minimize the damage.

6.For Hydraulic Oil tank, Low level alarm is present.

7.A

Tanker of 10000 GRT and more must be provided with two steering gear

systems, So in case of failure the steering gear change automatically to

the stand-by Steering gear system within 45 seconds, along-with alarm

for indication. It is provided for a reason, that if in case failure

occur the ship keep moving in the same direction.

#Cover image credit: http://marine-data.co.uk

Author Arpit Singh & Amit Article Requested by: kesavan s

#Cover image credit: http://marine-data.co.uk

Author Arpit Singh & Amit Article Requested by: kesavan s

Post a Comment