A boiler is a closed pressure vessel, in which water vapor is produced from distilled water / feed water. All boilers have a furnace or a combustion chamber in which fuel is combusted to release energy. Air is provided in the boiler furnace for assisting the combustion of the fuel. A large clearance between the combustion chamber and the water allows the transfer of combustion energy to the water, as heat. The boilers are equipped with a steam drum and a water drum, which ensure steam and water respectively, can be separated. It should also provide a variety of accessories and to ensure that the fuel, the supply of air and water is to meet the steam requirements.

VARIOUS USES OF STEAM ON SHIPS

For main engine propulsion/turbines (in case of steam ships)For power generation (to run steam turbo generators)

For running auxiliaries (in case of steam ships)

For soot blowing and for the steam atomized burners.

For fresh water generation (Evaporators)

For fire major fighting (steam drenching)

For heating duties (ME fuel oil heater, Galley supply, Purifier, Calorifier, Galley, Accommodation heating, Sea chests tracer lines for pipeline heating)

For cargo heating

For fuel tank heating

For deck machineries

For running Cargo pump turbines

For operating bilge, stripping and other steam driven pumps.

For tank washing in tanker ships and general cleaning.

For using as a steam ejector media for ejector pumps and vacuum devices

For Driving steam driven deck machineries like winches etc.

Pressures used:

The working pressure used in marine boilers will vary from boiler to boiler as required.For Tanker Vessels Medium pressure 17-30 bar(normally 16bar).

Boiler system in oil tankers:

Due to the high demand in the oil-Tankers, high capacity composite boilers or Dual pressure boilers are used. The main reason for the introduction of double pressure boiler is the use of modern boiler water pipes of high yield, without fear of load damage or contamination of Fuel oils. The basic construction is made of a D-Type boiler design upon which is mounted a Steam/Steam generator drum. Steam heating by the main boiler warms the water in the steam generator which full fill all the requirements for a propulsion pump, the heating load and fuel tanks and all other tasks of turbines.

The drum is initially filled with the primary quality of feed water and is well balanced. Make-up is limited to small amounts due to leaks and the fuel pump can be simple. An example of this could be an alternative pump driven by steam or air. The chemical treatment/dozing is simple and requires only minimal for the addition or rinsing. The above design shows super heater in the system but this is usually installed where the generated steam is required for the turbine alternators.

Secondary drum.

The U-shaped heating elements welded through the door of the shaft and at the end covered with the drum head. The tubes are well supported. In the lower part of the housing a manhole can be installed to allow access to the heating elements. The secondary drum also acts as a receiver for the exhaust gases of the steam boiler. Typical pressures above 63 bar (278degC) for the primary and 23.5deg (219degC) for the secondary. Primary pressure of 35bar (242degC) and closer to 15bar high pressure (198degC) proved to be sufficient to drive turbines for cargo oil pumps on tankers.

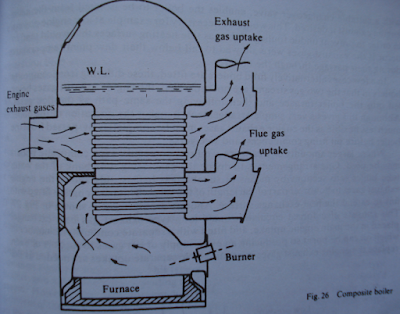

On another hand Composite boilers are a combination of oil boilers and exhaust gas economiser. When the diesel engine is at full load, the fuel burner starts only when the steam demand is higher than the production of steam from the exhaust gas of diesel engines. Composite boilers are so arranged that these can generate steam on Main engine exhaust gases or by burning oil in the furnace. In most cases the gas flows are kept separate each having its own uptake this permits the oil firing to be used in conjunction with the engine exhaust gases. By this means the output of steam can be maintained independent of the engine power.

Most of the tank type auxiliary boilers can be modified for composite firing, the modification consists of an additional tube nest added to basic oil fired design, the engine exhaust gases are circulated thru this tube nest so providing heat for generation of steam. In port stays boiler pressure is controlled by start/stop of burner at required pressure, and during sailing the pressure control is by excess steam dump valve.

But on which principle D-type water tube boiler work?

This boiler has 2 drums, an integral furnace with wall mounted burners and is often referred to as ‘D’ type boiler because of its shape. The furnace is at the side of the 2 drums and is surrounded on all sides by water tube walls. These water wall tubes are connected either to upper and lower headers or a lower header and the steam drum. The larger steam drum is placed above a smaller water drum , The two drums are connected to a large number of pipes of small diameter, which carry feed water. These small diameter pipes are known as the generating tubes that provide the main heat transfer surfaces for the generation of steam. The water circulates between the two drums with the aid of large diameter downcomers. The superheater is located through several rows of screen tubes covered between the drums. The fireproof material is used in the manufacture of the furnace, the burner wall and behind the water walls. The fire-resistant material acts as an insulator, which prevents heat loss. The boiler is also provided with a jacket for the combustion air, around the air control registers, which are surrounded by the burner.

# Various books, study material and other online sources has been refereed prior to writing this article but no part is copied or produced from any of the source but explained same thing in better detailed way.

Author Arpit Singh Article requested by: bilal ahmad

# Various books, study material and other online sources has been refereed prior to writing this article but no part is copied or produced from any of the source but explained same thing in better detailed way.

Author Arpit Singh Article requested by: bilal ahmad

3 comments

Thank you so much for sharing this useful and valuable information with us. I loved reading your blog. Keep sharing more information about Portable boiler.

Replythank you for sharing this innovative and helpful post i really like it your information...

ReplyHeating and Cooling Toronto

Hey there I am so thrilled I found your website, I really found you by error, while I was browsing on Askjeeve for something else, Anyhow I am here now and would just like to say kudos for a remarkable post and a all round enjoyable blog (I also love the theme/design), I don’t have time to look over it all at the moment but I have bookmarked it and also added your RSS feeds, so when I have time I will be back to read more, Please do keep up the awesome work. Steam boiler

ReplyPost a Comment